Hook up drawing of differential pressure transmitter Video

Differential Pressure Transmitter Explained hook up drawing of differential pressure transmitter.The IMV25 multivariable transmitter transmits digital process measurements of pressure, differential pressure, and process temperature, as well as internal sensor and electronics temperatures. It is an ideal solution when a number of individual measurements are to be brought into a system for monitoring, control, or calculation.

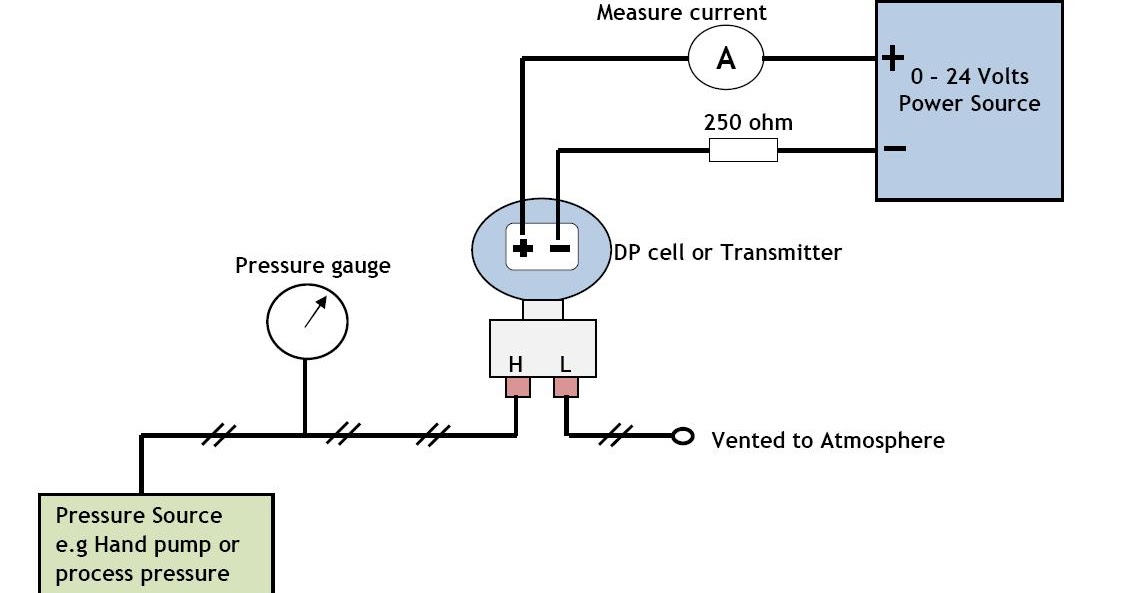

A single 4 to 20 mA analog output is also provided. Refer to TI b for process applicability with these wetted parts.

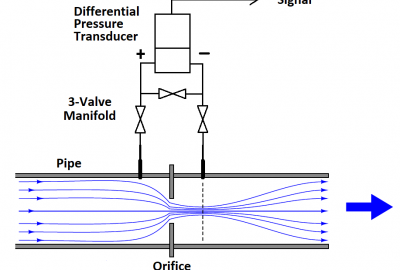

The most common means of collecting

Transmitter meets numerous agency requirements for hazardous area locations. Versions available to meet agency flameproof and zone requirements. Users having HART Communicators for other devices can have them upgraded with Invensys software to accommodate these transmitters. When configured for analog output, the 4 to 20 mA Output can be assigned to any one of the following variables:. This Windows-based software package displays measurements and has full calibration and configuration capability.

Energy & Power For All!

A digital indicator with on-board pushbuttons is available to display the measurement with a choice differental units. The pushbuttons allow zero and span adjustments, as well as routine local configuration changes. Biplanar Construction Figure 3 maintains the traditional horizontal process connections and vertical mounting by providing a cell body contained between two process covers, while still achieving light weight, small size, and high static pressure rating. This provides easy retrofit of any conventional differential pressure transmitter, and also is easily mounted in the horizontal position with vertical process connections, when required.

Medidor de notas musicais online

Process Covers Figure 3 are fully supported by the cell body over their entire height. This prevents bending and results in a highly reliable seal. Also, this provides dimensional stability to the process covers, ensuring that they will always mate properly with 3- valve bypass manifolds. Process Cover Bolts Figure 3 are enclosed to minimize corrosion and to minimize early elongation with rapid temperature increases. The design makes it less likely for the transmitter to release process liquid during a fire. Process Cover Gaskets are ptfe as standard; ptfe provides nearly universal corrosion resistance, and eliminates the need to select and stock various elastomers to assure process compatibility.

Light Weight provides ease of handling, installation, and direct mounting without requiring costly pipe stands. Traditional and low profile structures LP1 and LP2 are offered to accommodate differentkal to provide flexibility in transmitter installations. See paragraphs below. Traditional Structure The traditional structure Figure 4 utilizes the right angle design common to most DP transmitters in use throughout the world.

Process connections are oriented 90 degrees from the transmitter centerline. This traditional structure makes it easy to retrofit any transmitters of similar design. Sensor cavity venting and draining is provided for both vertical and horizontal transmitter installation, using innovative tangential connections to the sensor cavity Figures 5 and 6.]

In my opinion, it is an interesting question, I will take part in discussion.

It is reserve

You are mistaken. I can prove it. Write to me in PM, we will talk.